When a factory's production network becomes overloaded, what are the implications?

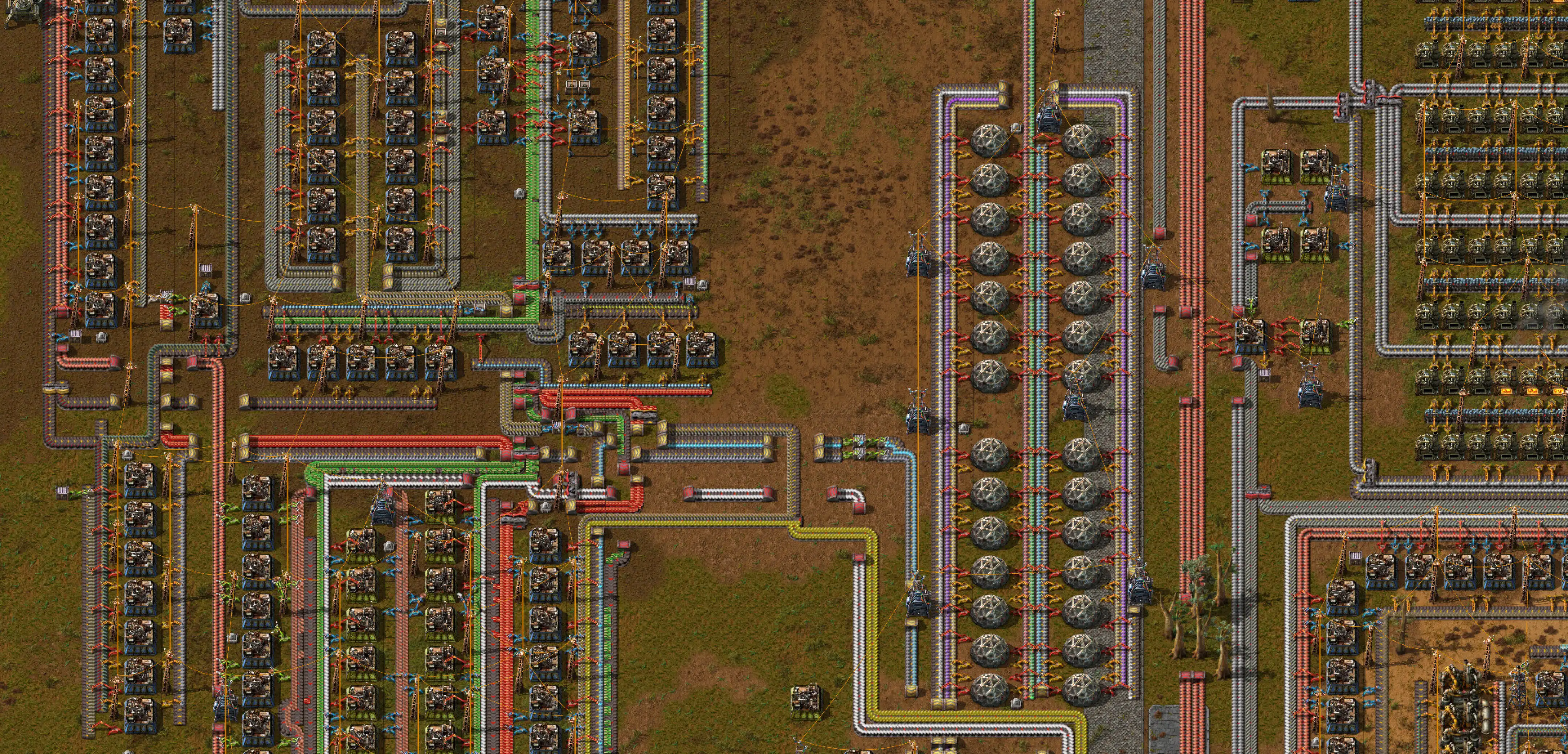

A production network in Factorio, or a similar game, can experience bottlenecks and inefficiencies when the flow of resources, especially raw materials and intermediate products, exceeds the capacity of the existing infrastructure. This can manifest as delays in product output, shortages of key components, and a general decline in overall production. For example, if a conveyor belt system designed to transport 100 units per minute is consistently receiving 150 units, congestion and delays will result. The system is essentially overwhelmed by the demand placed upon it.

This overextension can stem from several factors, including inadequate initial design, sudden increases in demand, or unforeseen changes in the production schedule. Addressing the issue effectively often requires a thorough analysis of the existing pipeline to identify areas of constraint. Solutions might include the addition of new conveyor belts, automated sorting systems, or a reconfiguration of the entire production chain. A careful review of raw material gathering, intermediate production, and final product delivery is crucial to understand the bottlenecks and introduce optimized solutions. Ultimately, maintaining a balanced and efficient network is vital to sustained high production levels.

Examining the overextended pipeline is now the crucial first step in the process of improving production efficiency. The next section will delve into specific strategies for identifying and correcting these bottlenecks in a Factorio setting.

Factorio Pipeline Overextension

An overextended Factorio pipeline signals a critical production issue. Understanding its multifaceted causes and effects is crucial for efficient resource management.

- Capacity limitations

- Demand surges

- Resource bottlenecks

- Inefficient routing

- Insufficient storage

- Production imbalance

- Outdated infrastructure

- Lack of automation

Overextended pipelines, characterized by capacity limitations and demand surges, often lead to bottlenecks and production halts. Resource bottlenecks, arising from insufficient supply, highlight the need for optimized resource gathering. Inefficient routing contributes to delays and waste, demanding a refined production layout. Insufficient storage exacerbates the problem, necessitating expanded storage capacity. Production imbalances between different stages reveal the need for a balanced flow of resources. Outdated infrastructure and a lack of automation require upgrades or optimization. Addressing these interconnected issues is essential for maintaining a stable and high-performing Factorio production system.

- February 23 Zodiac Sign Your Astrological Profile

- Ray Romano Everybody Loves Raymond Cast Now Where Are They

1. Capacity Limitations

Capacity limitations are a fundamental cause of an overextended Factorio pipeline. A system's capacity represents its maximum throughputthe maximum rate at which it can process resources or produce output. When the demand placed on a pipeline exceeds its capacity, the system is overextended, resulting in bottlenecks, delays, and ultimately, reduced efficiency. Insufficient infrastructure, such as inadequate conveyor belts or insufficient storage space, directly contribute to this condition.

Consider a scenario where a player's factory is designed to process 100 units of ore per minute. If the ore mining operation suddenly increases production to 150 units per minute, the pipeline's capacity is exceeded. This excess input overwhelms the processing steps, leading to backlogs and a corresponding drop in overall output. A similar effect arises if the throughput of a crucial intermediate step, like smelting, cannot keep pace with the input from mining or the demand from further down the production chain. Identifying and quantifying these capacity limits is essential for recognizing and rectifying an overextended pipeline.

The critical importance of understanding capacity limitations lies in proactive design and adaptation. A thorough assessment of the factory's processing rates, storage capacities, and transport mechanisms allows for the anticipation of potential bottlenecks. This preventative approach prevents the pipeline from becoming overextended in the first place. Alternatively, if an overextension does occur, understanding the limitations allows for focused and targeted solutions, such as adding more conveyor belts, optimizing logistics, or upgrading processing facilities. In short, acknowledging and mitigating capacity limitations is essential to maintaining a robust and efficient production network in Factorio.

2. Demand Surges

Sudden increases in demand pose a significant challenge to a Factorio production pipeline. A surge in the need for a particular product or resource can quickly overwhelm the existing infrastructure, leading to bottlenecks and ultimately, an overextended pipeline. This occurs when the rate at which resources are required exceeds the rate at which the system can produce or deliver them. The effect is analogous to a traffic jam; increased demand, without corresponding infrastructure improvements, creates delays and congestion.

Consider a player expanding their factory rapidly. Initially, production might be designed to satisfy average demand. However, an unexpected surge in demand for a specific component, perhaps due to a sudden increase in construction projects or an unforeseen increase in orders, may overwhelm the existing pipeline. This manifests as a buildup of incomplete products or raw materials, delaying the production of finished goods. The bottleneck restricts further stages from receiving their input, creating a domino effect that extends throughout the entire production chain. This situation highlights the need for a production system that can adapt to fluctuating demands, such as incorporating buffer storage or flexible production lines.

Understanding the correlation between demand surges and pipeline overextension is vital for proactive design and optimization. Recognizing potential future demand fluctuations through market analysis or historical data allows for the anticipation and implementation of mitigation strategies. Such strategies include establishing strategic buffer stockpiles, implementing flexible production scheduling, and strategically expanding capacity in anticipation of future growth. By proactively adapting to anticipated changes in demand, players can maintain a robust and resilient Factorio pipeline, ensuring consistent output and preventing costly production delays during periods of high demand.

3. Resource Bottlenecks

Resource bottlenecks are a critical factor contributing to an overextended Factorio pipeline. When the flow of essential resources is obstructed, it directly impacts the production process's efficiency and overall output. This impediment can manifest as shortages of raw materials, intermediate components, or finished goods, leading to delays and reduced throughput along the entire pipeline.

- Insufficient Supply of Raw Materials

A scarcity of raw materials, whether due to inadequate mining rates, insufficient transportation capacity, or external factors, immediately creates a bottleneck. This bottleneck impedes the production of downstream components and products. For example, if a factory relies heavily on iron ore, and mining operations fail to keep up with smelting demand, the entire pipeline will slow down. Consequently, the factory will struggle to meet output targets and will likely be operating below capacity.

- Inadequate Storage Capacity

Insufficient storage space for intermediate components can create a significant bottleneck. If storage buffers fill quickly, downstream processing steps are starved of necessary inputs. This situation occurs when the rate at which components are produced exceeds the rate at which they can be stored and used. For example, a lack of storage for processed lumber might delay the construction of furniture, causing a halt to the woodworking section and propagating back through the pipeline.

- Unbalanced Production Rates

Disparities in production rates between different stages of the pipeline can lead to imbalances, resulting in bottlenecks. If a particular component is created more quickly than the subsequent stage can consume it, the pipeline experiences an overabundance in that specific component. Conversely, if a later stage requires a component faster than the earlier stage produces it, the pipeline is starved of that component. This imbalance slows the whole process and creates a bottleneck.

- External Resource Constraints

External factors, such as supply chain issues or material shortages unrelated to the factory itself, can create significant resource bottlenecks. If a critical resource, like a specific type of circuit board, becomes unavailable, the entire production line dependent on that component can stall, no matter how well-optimized the internal factory infrastructure is.

These bottlenecks, stemming from insufficient raw materials, storage, or balanced production, and external factors, collectively contribute to the overextension of the Factorio pipeline. Addressing these constraints is vital to optimizing the production process and achieving desired throughput.

4. Inefficient Routing

Inefficient routing in a Factorio production pipeline directly contributes to its overextension. Poorly planned pathways for resources and products create bottlenecks, delays, and reduced throughput. This inefficiency arises from inadequate consideration of the flow of materials within the factory layout, failing to account for the volume and velocity of items being transported. A poorly designed routing system forces items to travel longer distances, leading to unnecessary delays in processing and increasing the time it takes to complete production cycles. Consequently, the overall throughput of the entire pipeline is reduced, causing it to become overextended.

Real-world examples highlight the significance of proper routing. Consider a factory where conveyors are haphazardly placed, forcing materials to take circuitous routes or causing congestion at junctions. This leads to delays and backlogs, impacting the entire production process. Similarly, a lack of automated sorting or prioritization systems can result in raw materials or intermediate products getting stuck, blocking the flow and causing a bottleneck. In essence, ineffective routing acts as a significant constraint, preventing the pipeline from effectively handling the required throughput. If the routing isn't optimized, the pipeline's overall capacity is diminished, and its effectiveness is hampered. A correctly designed routing system, conversely, ensures that resources move efficiently through the production process, reducing bottlenecks and increasing the pipeline's overall capacity.

Understanding the critical link between inefficient routing and pipeline overextension is paramount for optimizing production in Factorio. A careful layout, including strategic placement of conveyors, automated sorting, and prioritized pathways, is crucial for a smooth flow of materials. This optimization process, by addressing the inefficiencies of routing, directly enhances the pipeline's capacity. By avoiding unnecessary detours, increasing throughput rates, and preventing bottlenecks, players can maintain a balanced and high-performance production network, minimizing disruptions and maximizing efficiency.

5. Insufficient Storage

Insufficient storage capacity directly contributes to an overextended Factorio pipeline. When the rate of production outpaces the rate at which items can be stored, intermediate products and raw materials accumulate. This accumulation creates a bottleneck, disrupting the flow of resources throughout the entire production chain. The system becomes clogged, as items waiting to be processed overwhelm the available storage space. Consequently, the pipeline's capacity is exceeded, leading to delays and inefficiencies.

Consider a scenario where a factory produces components faster than they can be processed or stored in the downstream assembly line. Excess components accumulate, backing up the production line. Conveyor belts become congested, and the rate of output slows down dramatically. This bottleneck impacts subsequent stages of production, creating a ripple effect that slows the entire factory. Similarly, insufficient storage for raw materials can lead to shortages in the manufacturing process, forcing a halt in production until more raw materials are acquired. These situations highlight the critical role of adequate storage as a crucial component for maintaining a balanced and efficient production pipeline. Failure to anticipate and account for storage needs is a common cause of overextension.

Recognizing the connection between insufficient storage and pipeline overextension is vital for effective Factorio factory design. A carefully calculated storage capacity is essential to maintain a smooth flow of resources. By designing storage areas with sufficient capacity to accommodate production output, manufacturers can avoid bottlenecks and ensure a consistent production rate. This proactive approach minimizes delays and maximizes efficiency, thereby preventing the pipeline from being overextended. This understanding translates directly to real-world manufacturing practices, emphasizing the importance of strategic buffer stock and efficient inventory management.

6. Production Imbalance

Production imbalance, a significant contributor to an overextended Factorio pipeline, arises when the rates of production at different stages of the manufacturing process are not in sync. This asynchrony creates bottlenecks, disrupting the smooth flow of resources and ultimately reducing overall output. When one stage produces items faster than the subsequent stage can process them, a surplus builds up. Conversely, if a later stage demands items faster than the preceding stage can supply, a shortage occurs, both scenarios hindering the entire production chain. The result is a disruption in the overall flow, commonly resulting in the pipeline being overextended.

Consider a factory producing gears. If the gear-cutting station operates at a significantly higher speed than the assembly line that utilizes those gears, a surplus of gears accumulates. This excess effectively blocks the conveyor belts, creating a bottleneck and halting the production of finished products. Conversely, if the assembly line needs gears at a rate exceeding the gear-cutting station's output, the assembly line stalls, creating a shortage and slowing the entire production process. Both scenarios demonstrate how production imbalance directly contributes to an overextended pipeline by disrupting the flow of resources at critical junctures. This imbalance affects the efficiency of the entire system, from raw material gathering to final product delivery. Understanding the importance of a balanced production rate is pivotal to preventing and mitigating overextension.

Recognizing production imbalance as a key factor in pipeline overextension provides crucial insight for optimization. A balanced production schedule, where the output rate of each stage aligns with the requirements of the subsequent stages, ensures a steady flow of resources. This balance maintains the integrity of the pipeline, preventing bottlenecks and maximizing overall throughput. By analyzing and adjusting production rates to match the flow of resources, manufacturers can minimize the accumulation of surplus items and prevent bottlenecks, thus optimizing the production process and maintaining a robust pipeline. Ultimately, this understanding facilitates the design of a more efficient and resilient production system.

7. Outdated Infrastructure

Outdated infrastructure, characterized by obsolete or insufficient equipment, directly contributes to a Factorio pipeline's overextension. Inefficient machinery, inadequate transport systems, and limitations in processing capabilities place constraints on the overall throughput of the system. This necessitates frequent bottlenecks and delays in the production process, hindering the factory's ability to meet demand and potentially impacting profitability.

- Conveyor Belt Limitations

Outdated conveyor belts, whether due to their capacity or design limitations, often become a critical constraint. In a system designed for a lower throughput, introducing a large volume of raw materials or products can result in severe congestion and overextension. Existing conveyors may lack automation or have inadequate speed to maintain efficiency alongside a growing production rate. This leads to an accumulation of resources, slowing down the entire pipeline.

- Inefficient Processing Units

Obsolete processing units, such as smelting furnaces or assemblers, operate below their optimal efficiency. Their reduced capacity in processing raw materials or assembling intermediate components directly reduces the throughput of the production chain. Insufficient processing power in certain areas of the factory can become a bottleneck, causing other segments to become overextended to compensate. This can lead to imbalances and a cascade effect throughout the pipeline, necessitating frequent input adjustments to maintain a level output.

- Lack of Automation

The absence of automation in outdated infrastructure can create a major bottleneck. Manual processes, relying on human intervention, can be significantly slower and less consistent than automated systems. Maintaining the required throughput for a growing factory with manual processes quickly becomes impossible. Introducing new products or significant increases in existing products will lead to the production line becoming overextended, or lead to bottlenecks that need to be resolved.

- Inadequate Storage Capacity

Outdated infrastructure may include inadequate storage solutions. If storage facilities cannot accommodate the rate at which goods are produced or input into the factory, this will immediately cause issues. Excess items accumulate, leading to an inability to process incoming resources, which in turn leads to a blockage of the pipeline. Insufficient storage capacity, coupled with outdated or inefficient processing, leads to a system unable to sustain increasing demand. The pipeline quickly becomes overextended.

In summary, outdated infrastructure acts as a significant impediment to a smoothly functioning Factorio pipeline. Recognizing these limitations and planning for upgrades or replacements is crucial to avoid overextension and ensure sustained production. A proactive approach towards updating and modernizing infrastructure is essential for optimizing efficiency and achieving desired throughput levels in a Factorio setting.

8. Lack of Automation

A lack of automation in a Factorio production pipeline directly contributes to overextension. Manual processes, inherently slower and less consistent than automated counterparts, struggle to maintain throughput when demand increases. This disparity between production rate and demand results in a buildup of resources at various stages, creating bottlenecks and ultimately overextending the pipeline. The inability to efficiently process inputs and output commensurate with the scale of operations restricts overall productivity.

Consider a scenario where a player relies heavily on manual labor for resource gathering, processing, and assembly. As the factory expands and production targets increase, the rate of manual labor can't keep pace. This leads to raw materials piling up, intermediate components accumulating, and finished goods taking longer to reach the market. The pipeline becomes clogged, impacting the entire production chain. Such bottlenecks are a direct consequence of the lack of automation. Automated systems, on the other hand, can maintain a consistent and high output rate regardless of scaling, preventing the pipeline from becoming overextended. Real-world manufacturing examples demonstrate this: automated warehouses, assembly lines, and materials handling systems all drastically improve productivity by eliminating manual, time-consuming steps.

Understanding the link between lack of automation and pipeline overextension is crucial for effective factory design. A clear recognition of the limitations of manual processes empowers designers to proactively incorporate automation solutions. By implementing automated systems for tasks like mining, smelting, assembly, and logistics, the factory can operate at peak efficiency, minimizing resource buildup and maintaining a consistent throughput. This approach ensures production remains robust and adaptable to growing demand, preventing the detrimental effects of an overextended pipeline. Consequently, the ability to scale production effectively and sustainably hinges on the appropriate level of automation incorporated within the production pipeline.

Frequently Asked Questions

This section addresses common concerns regarding overextended production pipelines in Factorio. Understanding these issues is crucial for optimizing resource management and maximizing factory output.

Question 1: What causes a Factorio pipeline to become overextended?

Several factors contribute to pipeline overextension. Insufficient infrastructure, such as inadequate conveyor belts or storage capacity, can overwhelm the system. Sudden increases in demand for a specific product or resource may exceed the pipeline's current capacity. Imbalances in production rates between different stages, where one section produces faster than another can handle, can create bottlenecks. Finally, inefficient routing of resources or inadequate automation can significantly impact the overall throughput and lead to overextension.

Question 2: How can I identify an overextended pipeline?

Signs of an overextended pipeline include bottlenecks, noticeable delays in production, and excessive resource accumulation at specific points in the manufacturing chain. Conveyor belts that are consistently backed up or overflowing storage areas are clear indicators. Monitoring production rates and comparing them to capacity limits can reveal imbalances. A thorough analysis of resource flow, bottlenecks, and bottlenecks can help identify the precise areas of concern.

Question 3: What are the consequences of an overextended pipeline?

The consequences of an overextended pipeline include reduced overall output, increased production times, and potential shortages of crucial components further down the line. These issues can lead to a cascade of delays and a significant decrease in the efficiency of the entire factory. In extreme cases, overextension can lead to production grinding to a halt.

Question 4: How can I fix an overextended pipeline?

Addressing an overextended pipeline requires a systematic approach. This often involves upgrading infrastructure to increase capacity, optimizing resource routing to streamline movement, and implementing automation to improve processing speed. Identifying bottlenecks through thorough analysis and implementing targeted solutions are essential steps. Considering alternative production strategies and improving resource allocation can further enhance efficiency. Adding buffer storage or optimizing logistics can help manage fluctuating demand.

Question 5: What preventative measures can I take to avoid pipeline overextension?

Preventing pipeline overextension involves proactive planning. Carefully assessing and planning production rates and capacities are essential for preventing bottlenecks from emerging. Ensuring adequate storage capacity to handle potential increases in demand is critical. Efficient routing and the strategic application of automation are crucial to maintaining optimal throughput. Regularly monitoring resource flow and production output allows for early detection of potential issues, enabling preemptive adjustments to maintain a balanced system.

By understanding these frequently asked questions, players can address the challenges posed by an overextended production pipeline in Factorio and maintain a consistently high-performing factory.

The next section will delve into specific strategies for optimizing production pipelines, including detailed design examples.

Conclusion

This article explored the multifaceted nature of overextended production pipelines in Factorio. Key factors contributing to this issue included capacity limitations, demand surges, resource bottlenecks, inefficient routing, inadequate storage, imbalanced production, outdated infrastructure, and a lack of automation. Each of these elements creates bottlenecks and stalls the flow of resources, impacting overall factory output. The article highlighted the critical importance of a balanced production system, emphasizing the need for proactive assessment and strategic mitigation strategies. Addressing these underlying issues is essential for maintaining optimal factory performance and ensuring sustained production.

Ultimately, an overextended pipeline represents a significant challenge to achieving desired output levels in a Factorio game setting. Proactive planning, continuous monitoring, and strategic implementation of improvements are crucial to maintain operational efficiency. Failure to address pipeline overextension can lead to significant losses in productivity and profitability. Thus, a well-designed, adaptable, and responsive production pipeline is critical for success in Factorio. Effective resource management and consistent optimization are paramount for sustained success and consistent output in a dynamic and demanding game environment.